DESIGN

FREE CONSULTANCY

BUDGET FRIENDLY

GET A QUOTE

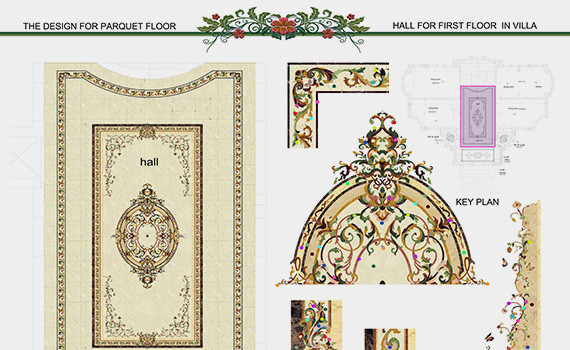

PFM has developed a special expertise in the waterjet process of cutting, that enables the most intricate waterjet inlay designs. Inlay designs that were previously impossible to achieve, now possible and beyond imagination. This has opened up the possibility of creating the most intricate designs from small medallions to large carpet designs; including wall panels. Introduce lighting, and you bring the designs to a whole new dimension.

DESIGN

MARBLE WATERJET

Installation Friendly

As the largest and most experienced fabricator of architectural materials using waterjet technology in Guangzhou. PFM offers a wide range of related services and processes. PFM has experienced professionals guide you through every step.

As the largest and most experienced fabricator of architectural materials using waterjet technology in Guangzhou. PFM offers a wide range of related services and processes, and experienced professionals guide you through every step.

The size and the shape details(CAD) will be put into the water jet CNC equipment. Then the marble pattern pieces will be cut by a high pressure waterjet machine to any CAD design desired.

According to the drawing, the pattern pieces will be assembled with glue.When it totally dries, we cover the back of the entire marble with a net of fiber and stone powder resin. At the same time ,smoothing the surface in order to strengthen it.

Place the marble waterjet on the work platform, grinding polished, until the mirror luster appears.

Waterjet cutting, a process where a jet stream of water is forced through a tiny nozzle at a very high pressure, provides many unique capabilities and advantages that allow the cutting of materials and parts often considered too costly or even impossible with other methods. Our waterjet cutters are able to cut through the hardest of materials , leaving smooth, extremely accurate edges.

Our state-of-the-art Waterjet cutting equipment offers nozzle pressure of 60,000 psi, with a maximum cutting width and length is 1200x2400mm(4x8'). We hold cutting tolerances as close as ±0.1mm(±0.004"), handling materials up to 100mm(4" )thick.

Water jet cutting is an environmentally friendly technology as well. It does not create dust, grindings, chips, or chemical air pollution. Cutting oils or emulsions are not needed with this process. Waste products of waterjet jet are inert and easily disposed of or reused.